Understanding Hydraulic Final Drive Motors: A Deep Dive

In the realm of machinery and engineering, hydraulic final drive motors represent a pivotal component in achieving optimal performance and efficiency. Engineered to provide precision and power, these devices are integral to various automotive and industrial applications. This article provides a comprehensive guide to understanding hydraulic final drive motors – their functionality, advantages, and significance in both Auto Parts & Supplies and Motorcycle Parts & Supplies.

What is a Hydraulic Final Drive Motor?

A hydraulic final drive motor is a type of motor that converts hydraulic energy into mechanical energy. It plays a crucial role in machinery, specifically in applications where high torque and precision control are necessary. By utilizing hydraulic fluid to transfer energy, these motors provide reliable and efficient power solutions, making them a preferred choice in many industries.

How Hydraulic Final Drive Motors Work

The operation of a hydraulic final drive motor involves several key components:

- Hydraulic Fluid: This is the medium through which energy is transferred. The fluid pressure is generated by a hydraulic pump.

- Drive Shaft: The drive shaft transmits power from the motor to the machinery or vehicle.

- Control Valves: These are essential for regulating the flow of hydraulic fluid, thus controlling the speed and torque.

- Gear Sets: Gear sets within the motor enhance torque output, allowing for powerful and efficient energy transfer.

As hydraulic fluid enters the motor, it creates pressure that forces the internal gears to rotate. This rotation produces mechanical energy, which can then be utilized to drive wheels, tracks, or other machinery components.

Types of Hydraulic Final Drive Motors

Hydraulic final drive motors can be categorized into different types based on their design and application:

1. Gear Motors

These motors utilize an internal gear mechanism to convert hydraulic energy into mechanical power. They are known for their compact design and high efficiency, making them suitable for small spaces.

2. Piston Motors

Piston motors operate by using hydraulic pressure to move pistons within cylinders. This design allows for adjustable displacement, enabling better control over speed and torque.

3. Vane Motors

Vane motors consist of rotating vanes that interact with hydraulic fluid to produce motion. They are favored for their simplicity and high speed.

Advantages of Hydraulic Final Drive Motors

Implementing a hydraulic final drive motor in machinery offers a multitude of benefits:

- High Torque Output: These motors are capable of generating significant torque, making them ideal for heavy-duty applications.

- Precise Control: Hydraulic systems allow for precise control of speed and movement, enhancing operational efficiency.

- Compact Design: Many hydraulic motors are designed to be compact, saving valuable space in machinery layouts.

- Durability: Hydraulic motors are built to withstand tough environments, providing long-lasting performance.

- Flexibility: They can be used in a variety of applications, from construction machinery to agricultural equipment.

Applications of Hydraulic Final Drive Motors

Hydraulic final drive motors find their applications in numerous fields, including:

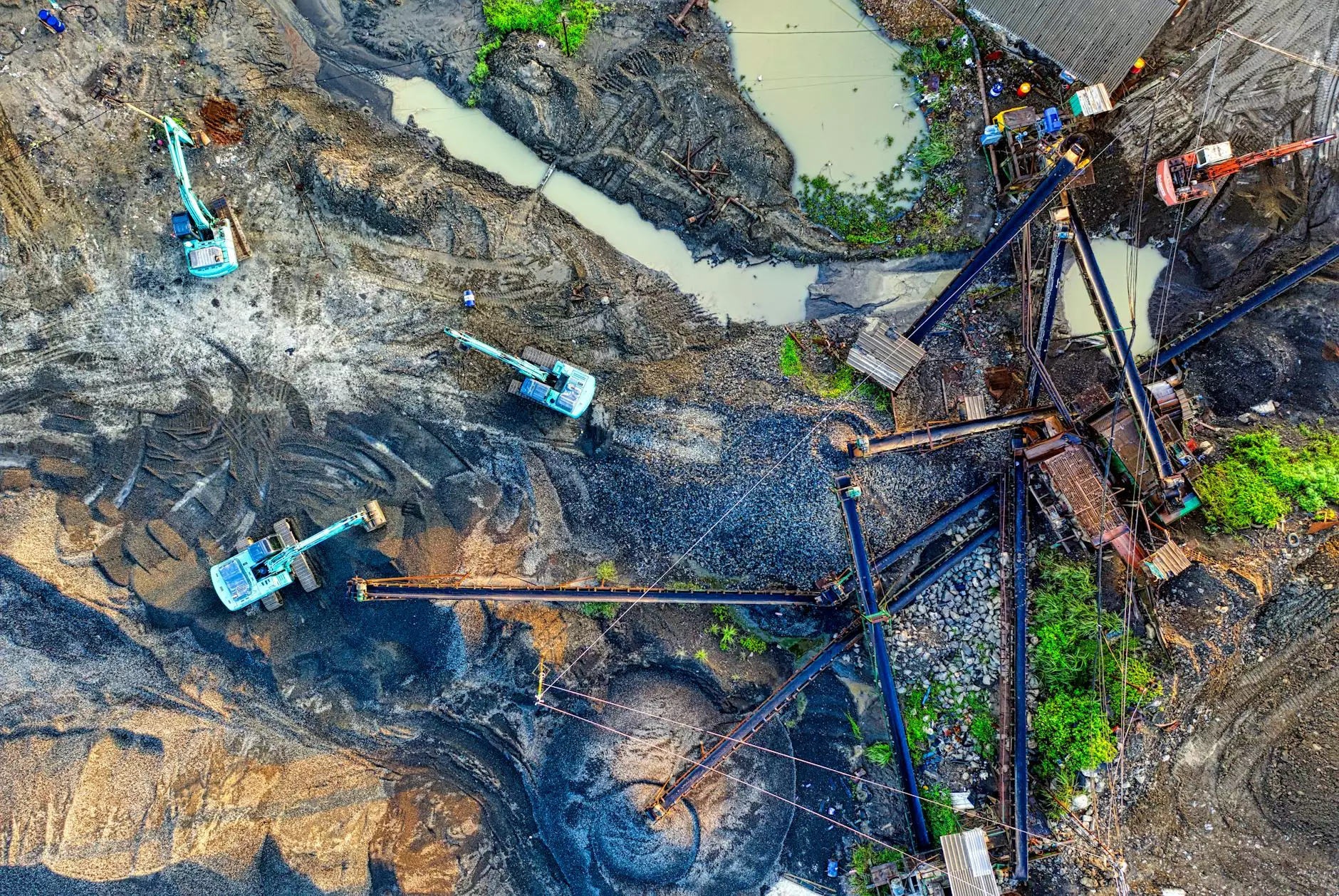

1. Construction Machinery

In construction, these motors are essential for powering excavators, bulldozers, and other machinery that require robust torque and control.

2. Agricultural Equipment

Hydraulic motors are used in equipment such as tractors and harvesters, allowing for precise maneuvers and powerful lifting capabilities.

3. Forestry and Mining

In forestry and mining operations, hydraulic final drive motors operate heavy machinery like logging trucks and mining drills, delivering the strength needed to handle extreme conditions.

4. Automotive Applications

For automotive applications, hydraulic final drive motors enhance the performance of vehicles by improving acceleration and torque delivery.

Choosing the Right Hydraulic Final Drive Motor

Selecting the appropriate hydraulic final drive motor for your application involves considering several factors:

- Torque Requirements: Assess the torque requirements of your machinery to ensure compatibility.

- Size Constraints: Ensure that the motor fits within the space constraints of the equipment.

- Operating Conditions: Evaluate the environment where the motor will operate, including temperature and exposure to dirt or moisture.

- Efficiency: Look for motors with high efficiency ratings to minimize energy loss.

- Manufacturer Reputation: Choose motors from reputable manufacturers known for quality and durability.

Maintenance Tips for Hydraulic Final Drive Motors

To ensure the longevity and efficiency of your hydraulic final drive motor, regular maintenance is essential. Here are some tips:

- Regular Fluid Checks: Monitor hydraulic fluid levels and quality to prevent damage.

- Inspect Seals and Hoses: Check for leaks and wear, as these can significantly impact performance.

- Clean Filters: Regularly clean or replace filters to ensure uninterrupted fluid flow.

- Monitor Temperature: Maintain operating temperatures within recommended limits to avoid overheating.

- Professional Servicing: Schedule professional inspections and servicing routinely to catch potential issues early.

Conclusion

In conclusion, hydraulic final drive motors are vital components in modern machinery, contributing to enhanced efficiency and performance across various sectors. Their ability to deliver high torque and precise control makes them indispensable in applications ranging from construction to agriculture. By understanding their mechanics, types, advantages, and maintenance requirements, businesses can make informed decisions that lead to optimized operations and increased productivity.

To explore high-quality hydraulic final drive motors and other auto parts, visit Shop Hydraulic America. Whether you're looking for reliable components for your construction equipment or high-performance parts for motorcycles, our extensive inventory is designed to meet your needs.